Location : Tiruppur, Tamil Nadu

Site area : 36,000 sqft

Built area : 56,900 sqft

Project status : On-going

Project Team : Pradeep Arumugam, Vijay Pillai, Mareeswaran, Vimal john

Project Type : Factory

WEAVE

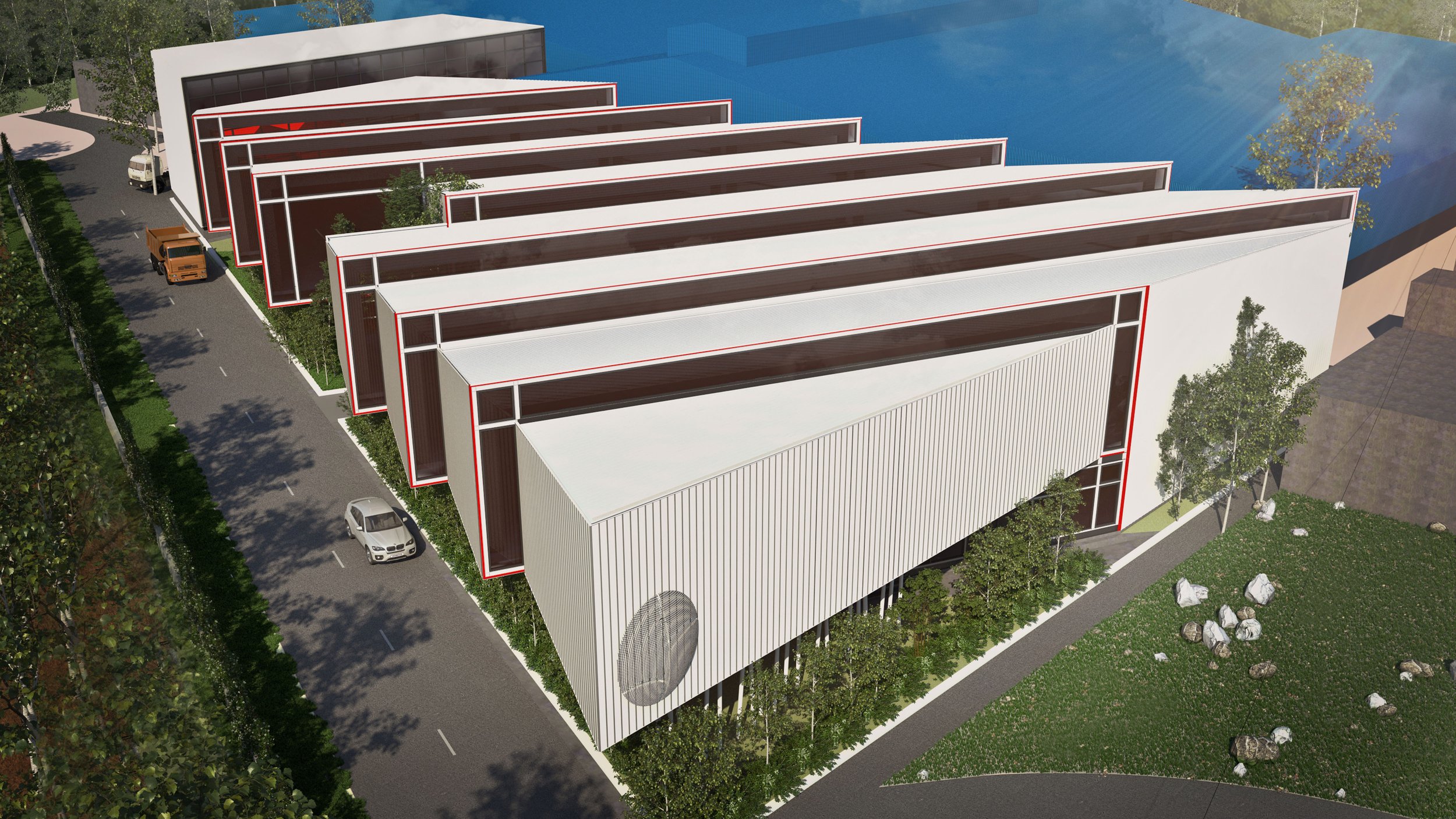

Succession of volumes,

Floating high above the ground

Symmetrical and visually porous,

Each seeking out the north sun

That usher in diffused light.

The site within a factory complex was originally intended to be a pond for collecting rainwater. The customer didn’t decide to include a spinning factory on the property until much later. The entire industrial space was raised 20’ above the ground, leaving room for vegetation, in order to preserve the functionality of the natural landform. This enormous factory facility is the first of its kind in India and houses a spinning factory on the first level that is entirely above the ground.

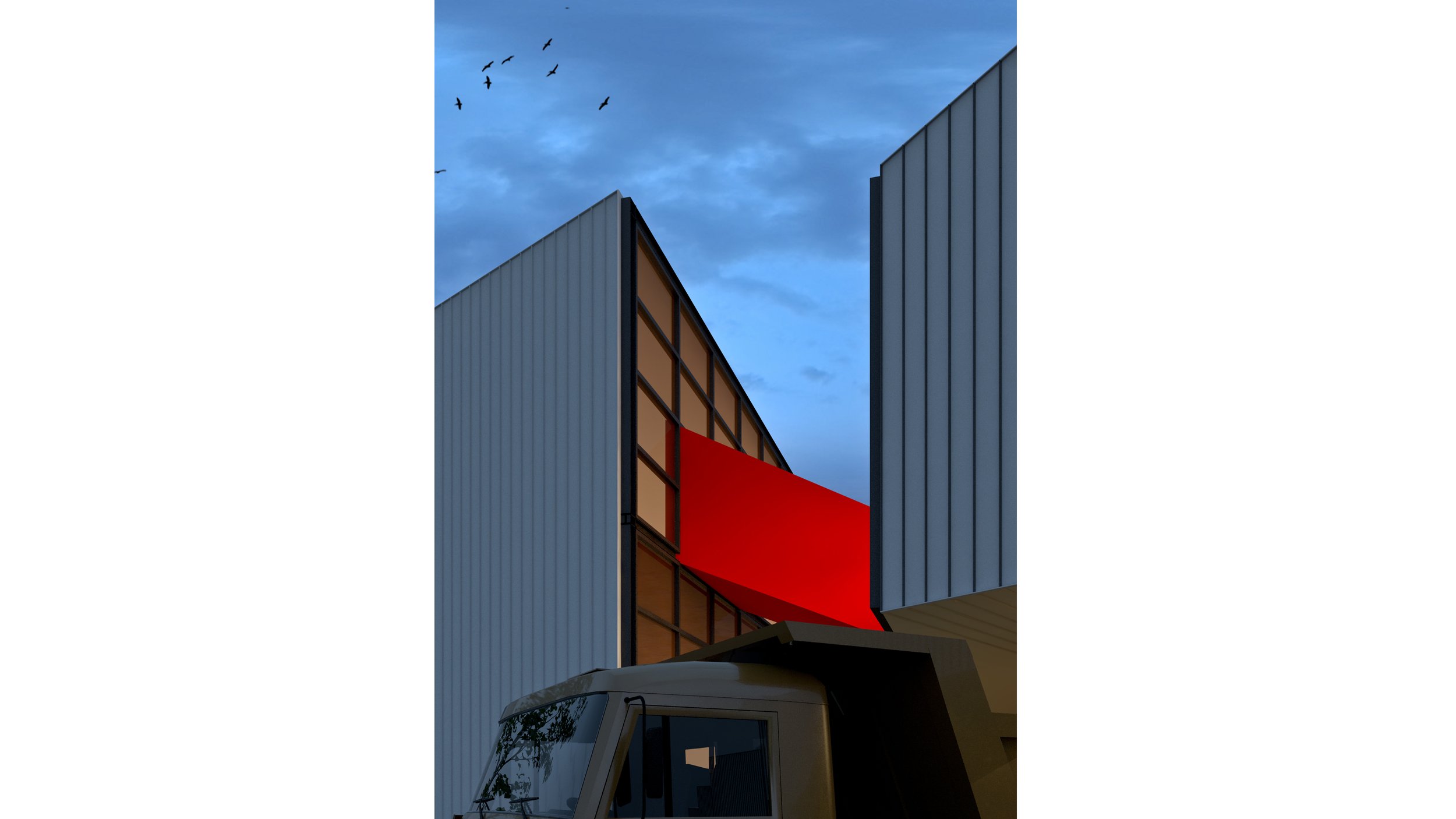

A factory environment needs strong Illumination because there is a lot of manual labour and checking done there. Even better would be natural daylighting, which not only saves energy but also benefits the workers’ physical and mental well-being. A northlight truss has been incorporated into the building’s design to guarantee ample natural daylighting. This truss has windows on the northern end and several, succeeding roofs that slope from north to south. The orientation of the structure toward the north also helps to limit solar gain and prevent inside warmth, allowing for the most benefit from natural daylighting.

The glass utilised In the north light truss was continued throughout the northern façade of each succeeding volume, and these volumes also began to widen slightly and project outside slightly from the volume in front. As a result, the enlarged section received diffused daylighting throughout the day and had easy visual access within the spinning factory thanks to the two volumes being connected by a glass layer.

Prefabrication was used in the building’s manufacture and construction, which had many advantages including long durability, simple assembly, lower costs, and, most importantly, improved the building’s green credentials. These materials, which are lightweight as well, support the idea of lifting the entire structure. The building’s whole material palette is made up of glass and galvanised aluminium sheet, which gives the structure a distinctive elegance and modern feel while also giving it a harsh and robust appearance.

The floor designs were created while taking into account the standards and specifications of a spinning mill, as well as the space requirements for essential tools and machines.